Positive Displacement Pumps vs. Centrifugal Pumps: The Complete Guide

If there’s one guarantee in life, it’s that whatever liquid or matter you’re looking to shift, there is already a perfectly designed pump ready to pump it.

But if you’re new to the pump industry, the vast number of technical pump types on offer can make it hard to find the ideal pump for your situation.

Take positive displacement and centrifugal pumps for example. Two of the most commonly used pumps in the industry, but the differences between them are minimal and this can make it tricky when deciphering which pump should be used in different scenarios.

Fortunately, if you are feeling overwhelmed by the differences between positive displacement and centrifugal pumps, you don’t need to continue living this way.

By learning just a few simple differences between these pump types, you will be able to make a confident purchase decision that’s right for your pool.

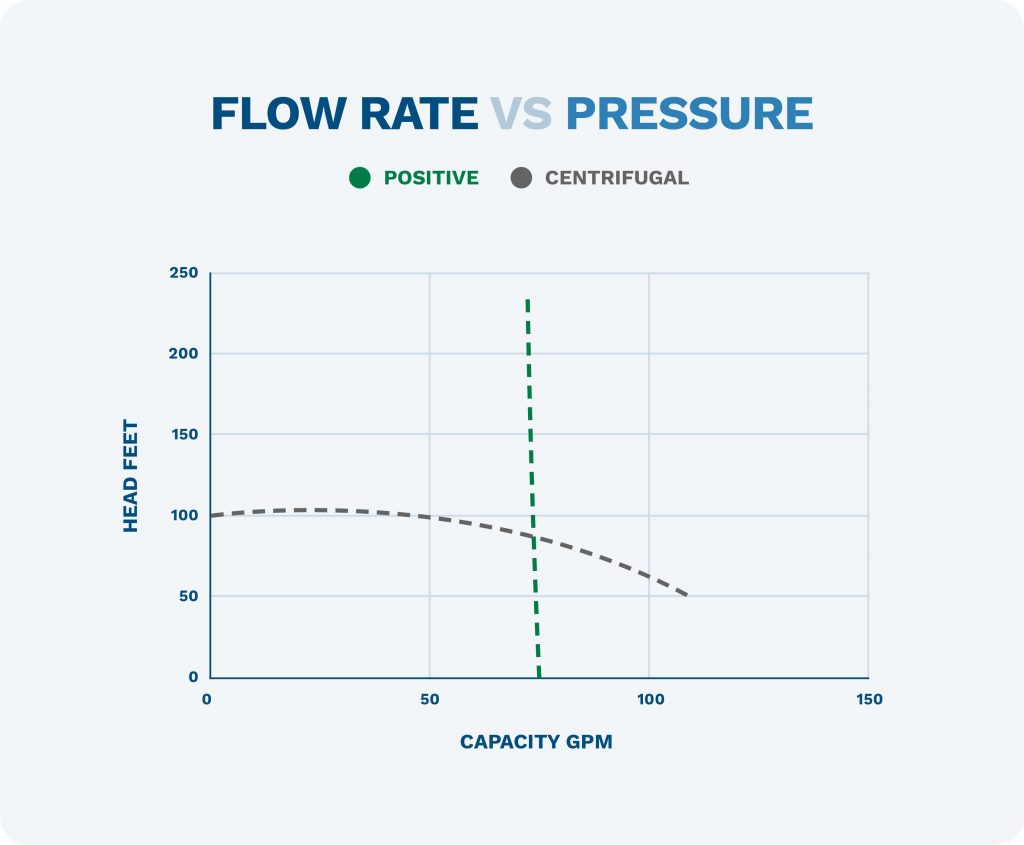

As you can see in the graphic above, a positive displacement pump will perform at almost the exact same pressure regardless of distance and capacity.

On the other hand, a centrifugal pump’s flow rate will start to decrease when the capacity is increased.

Key Learning: From this graphic, you can learn that a positive displacement pump is an ideal choice when you need a continual level of pressure when pumping a large amount of liquid.

As you can see in the graphic above, a positive displacement pump will perform at almost the exact same pressure regardless of distance and capacity.

On the other hand, a centrifugal pump’s flow rate will start to decrease when the capacity is increased.

Key Learning: From this graphic, you can learn that a positive displacement pump is an ideal choice when you need a continual level of pressure when pumping a large amount of liquid.

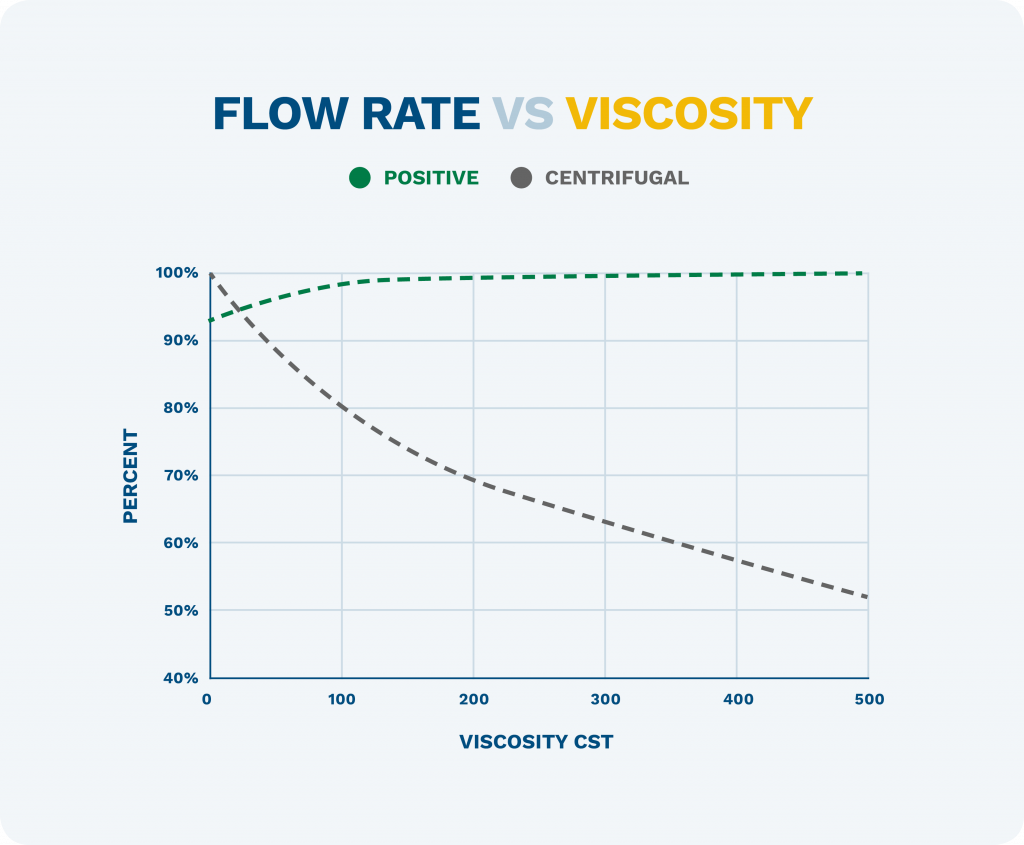

In this graphic, we cross-reference flow rate and viscosity. You can see that as the viscosity increases, the centrifugal pump’s performance begins to fail. The performance fails in a linear fashion as the viscosity increases.

On the other hand, the positive displacement pump’s performance increases as the viscosity initially increases, and then continues at a steady rate regardless of the viscosity level of the liquid.

Key Learning: From this graphic, you can learn that a positive displacement pump is an ideal choice when pumping liquids with a high level of viscosity.

In this graphic, we cross-reference flow rate and viscosity. You can see that as the viscosity increases, the centrifugal pump’s performance begins to fail. The performance fails in a linear fashion as the viscosity increases.

On the other hand, the positive displacement pump’s performance increases as the viscosity initially increases, and then continues at a steady rate regardless of the viscosity level of the liquid.

Key Learning: From this graphic, you can learn that a positive displacement pump is an ideal choice when pumping liquids with a high level of viscosity.

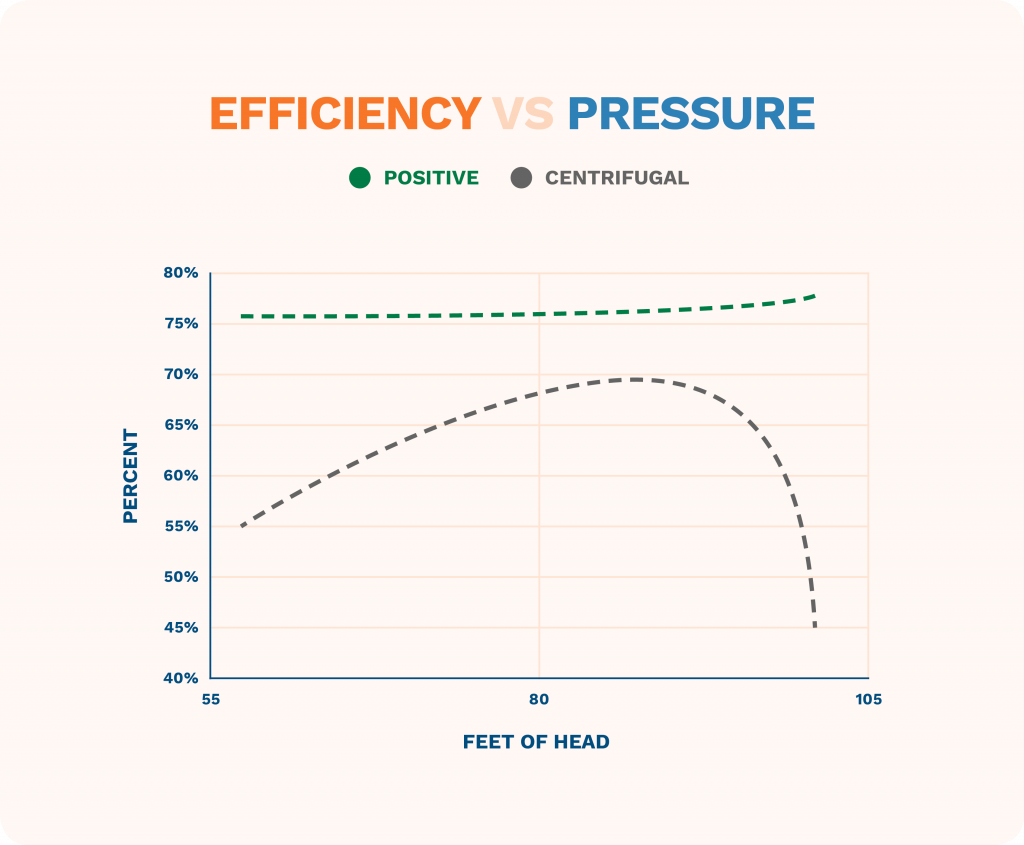

In this graphic, we cross-reference efficiency and pressure. The two key findings are clear to see.

Key Learning: From this graphic, you can learn that a positive displacement pump is the ideal choice when you have variable and unknown levels of pressure and need to pump as efficiently as possible.

In this graphic, we cross-reference efficiency and pressure. The two key findings are clear to see.

Key Learning: From this graphic, you can learn that a positive displacement pump is the ideal choice when you have variable and unknown levels of pressure and need to pump as efficiently as possible.

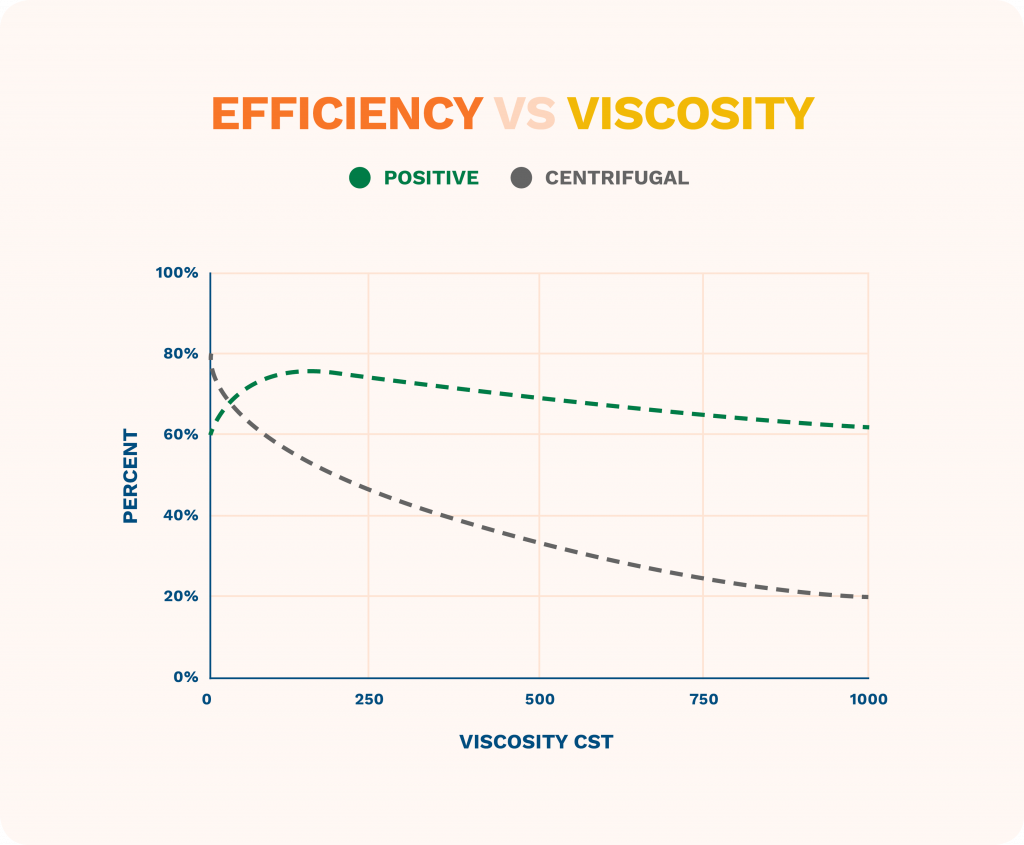

In our final comparison, we cross-reference efficiency and viscosity. As you may have guessed, the efficiency of a positive displacement pump only drops slightly as the viscosity of the liquid increases. This is due to the positive displacement pump’s superior ability to handle solids and pump liquids at a constant rate, regardless of the viscosity of the liquid.

On the other hand, the centrifugal pump efficiency drops off dramatically as the viscosity increases. One thing to note is that the centrifugal pump is much more efficient at low levels of viscosity.

Key Learning: The centrifugal pump is the more efficient pump at low levels of viscosity, whereas the positive displacement pump is the more efficient pump at high levels of viscosity.

In our final comparison, we cross-reference efficiency and viscosity. As you may have guessed, the efficiency of a positive displacement pump only drops slightly as the viscosity of the liquid increases. This is due to the positive displacement pump’s superior ability to handle solids and pump liquids at a constant rate, regardless of the viscosity of the liquid.

On the other hand, the centrifugal pump efficiency drops off dramatically as the viscosity increases. One thing to note is that the centrifugal pump is much more efficient at low levels of viscosity.

Key Learning: The centrifugal pump is the more efficient pump at low levels of viscosity, whereas the positive displacement pump is the more efficient pump at high levels of viscosity.

How does a centrifugal pump work?

A centrifugal pump works by continually transferring the kinetic energy of an electric motor to liquid by spinning an impeller (propeller). The impeller rotates like an aeroplane engine, drawing the liquid into the pump at an increased velocity. The increased velocity helps transfer the liquid to the pump outlet.What are the benefits of a centrifugal pump?

Centrifugal pumps are quite popular in the pumping industry and have a variety of benefits over positive displacement pumps. These include: - The simplistic design of a centrifugal pump often makes them cheaper than positive displacement pumps - With few moving parts, centrifugal pumps are often quite cheap to maintain and repair - The compact design makes them the ideal pump choice when space is at a premiumHow does a positive displacement pump work?

Positive displacement pumps do not use an impeller. Instead, they use rotating, reciprocating or pulsing parts to shift liquid. They work by trapping a fixed volume of water in one of the pump chambers. As the rotating, reciprocating or pulsing parts move, the liquid is forced out of the pump. It does this over and over in a constant back and forth motion.What are the benefits of a positive displacement pump?

Compared to centrifugal pumps, positive displacement pumps operate at a slightly slower speed. This makes them superior to centrifugal pumps in a variety of ways. These include: - Ability to handle varying levels of viscosity - Maintain a higher level of viscosity, pressure and flow - Pump at a higher rate of pressure - Ability to maintain a constant speed and flow - Their capacity is not affected by the operation pressure - They do not need to be completely sealedWhat applications are centrifugal pumps used for?

Centrifugal pumps are ideal if you are pumping liquids of low viscosity. They work well in high flow rate, low-pressure installations, which make them ideal for pumping large volumes of liquid. Centrifugal pumps do not work well with high viscosity liquids. For example, thick food items like honey can create friction within the impellers and can reduce the performance of the pump. Centrifugal pumps are ideal for the following industrial systems: - Industrial water supply - Seawater transfer - Air conditioning systems - Industrial boiler feed - Thin fuel transfer - Industrial washing - Firefighting - Irrigation The most common pump types to use a centrifugal pump in a residential system are: • Circulation pumps (central heating pumps) which are used to circulate water in closed systems that provide heat, air conditioning and hot water • Shower or home booster pumps which are used to increase the pressure of cold water in a system • Condensate pumps which are used to collect condensate in condensing (steam) boilers • Well (borehole) supply pumps which are used to supply water from wells, and come in above-ground and submersible versions • Some centrifugal pumps are used exclusively for industrial purposes. These pumps include industrial pumps and waste-water pumpsWhat applications are positive displacement pumps used for?

Positive displacement pumps are ideal if you are pumping liquids with a high viscosity. They work well in high-pressure systems with relatively low flow rates. Positive displacement pumps are usually chosen in a situation where a centrifugal pump would fail to handle solids and difficult liquid conditions. Keep in mind, there are two different positive displacement pump classifications. These are: • Rotary • Reciprocating In a reciprocating pump, the fluid flows back and forth propelled by a mobile object, usually a piston or diaphragm. The liquid is released when the piston or diaphragm moves. On the other hand, a rotary pump uses one part or several parts to move the fluid in a circular fashion. In each revolution of the pump, the liquid is discharged away from the pump. Positive displacement pumps are ideal for the following industrial systems: - Industrial oil supply - Sewage systems - Waste oil disposal - Food industry - SlurriesWhich pump type offers the best performance?

Both a centrifugal and a positive displacement pump will offer a high level of performance when used in the ideal system. In the visual graphics below, you can compare how a centrifugal and positive displacement pump will perform under different factors and criteria. This will help you identify which pump is ideal for your system.Flow Rate vs. Pressure

As you can see in the graphic above, a positive displacement pump will perform at almost the exact same pressure regardless of distance and capacity.

On the other hand, a centrifugal pump’s flow rate will start to decrease when the capacity is increased.

Key Learning: From this graphic, you can learn that a positive displacement pump is an ideal choice when you need a continual level of pressure when pumping a large amount of liquid.

As you can see in the graphic above, a positive displacement pump will perform at almost the exact same pressure regardless of distance and capacity.

On the other hand, a centrifugal pump’s flow rate will start to decrease when the capacity is increased.

Key Learning: From this graphic, you can learn that a positive displacement pump is an ideal choice when you need a continual level of pressure when pumping a large amount of liquid.

Flow Rate vs. Viscosity

In this graphic, we cross-reference flow rate and viscosity. You can see that as the viscosity increases, the centrifugal pump’s performance begins to fail. The performance fails in a linear fashion as the viscosity increases.

On the other hand, the positive displacement pump’s performance increases as the viscosity initially increases, and then continues at a steady rate regardless of the viscosity level of the liquid.

Key Learning: From this graphic, you can learn that a positive displacement pump is an ideal choice when pumping liquids with a high level of viscosity.

In this graphic, we cross-reference flow rate and viscosity. You can see that as the viscosity increases, the centrifugal pump’s performance begins to fail. The performance fails in a linear fashion as the viscosity increases.

On the other hand, the positive displacement pump’s performance increases as the viscosity initially increases, and then continues at a steady rate regardless of the viscosity level of the liquid.

Key Learning: From this graphic, you can learn that a positive displacement pump is an ideal choice when pumping liquids with a high level of viscosity.

Efficiency vs. Pressure

In this graphic, we cross-reference efficiency and pressure. The two key findings are clear to see.

Key Learning: From this graphic, you can learn that a positive displacement pump is the ideal choice when you have variable and unknown levels of pressure and need to pump as efficiently as possible.

In this graphic, we cross-reference efficiency and pressure. The two key findings are clear to see.

Key Learning: From this graphic, you can learn that a positive displacement pump is the ideal choice when you have variable and unknown levels of pressure and need to pump as efficiently as possible.

Efficiency vs. Viscosity

In our final comparison, we cross-reference efficiency and viscosity. As you may have guessed, the efficiency of a positive displacement pump only drops slightly as the viscosity of the liquid increases. This is due to the positive displacement pump’s superior ability to handle solids and pump liquids at a constant rate, regardless of the viscosity of the liquid.

On the other hand, the centrifugal pump efficiency drops off dramatically as the viscosity increases. One thing to note is that the centrifugal pump is much more efficient at low levels of viscosity.

Key Learning: The centrifugal pump is the more efficient pump at low levels of viscosity, whereas the positive displacement pump is the more efficient pump at high levels of viscosity.

In our final comparison, we cross-reference efficiency and viscosity. As you may have guessed, the efficiency of a positive displacement pump only drops slightly as the viscosity of the liquid increases. This is due to the positive displacement pump’s superior ability to handle solids and pump liquids at a constant rate, regardless of the viscosity of the liquid.

On the other hand, the centrifugal pump efficiency drops off dramatically as the viscosity increases. One thing to note is that the centrifugal pump is much more efficient at low levels of viscosity.

Key Learning: The centrifugal pump is the more efficient pump at low levels of viscosity, whereas the positive displacement pump is the more efficient pump at high levels of viscosity.